A major new research centre that will help test, certify and deploy new sustainable aviation fuels – the first of its kind in the UK – has reached a key milestone in its construction.

The Sustainable Aviation Fuels Innovation Centre (SAF-IC), part of the University of Sheffield Energy Institute, is set to give the UK much-needed testing capabilities to help producers of sustainable aviation fuels bring their fuels to the market.

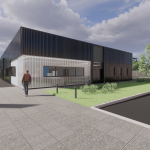

Located in the University of Sheffield Innovation District, home to the University of Sheffield Advanced Manufacturing Research Centre (AMRC) – a hugely successful blueprint for university and industry R&D on the border of Sheffield and Rotherham – the new centre will establish South Yorkshire as the UK’s leading place for R&D in sustainable aviation fuels.

The facility will work in combination with the neighbouring Translational Energy Research Centre (TERC) – a national pilot-scale testing facility that is also part of the University of Sheffield – to support state-of-the-art research and provide much-needed testing capabilities to help prepare sustainable aviation fuels for commercial use.

Together with TERC, SAF-IC will be the first centre in the UK to be able to capture CO₂, produce green hydrogen, convert them into sustainable aviation fuels and analyse their performance all in one single location.

The centre will help to bridge the gap in bringing new sustainable aviation fuels to market. It is able to help evaluate, test and characterise new fuels, which will help to accelerate regulatory approvals of new fuels and aid in their deployment.

Jointly funded by the European Regional Development Fund and the University of Sheffield, construction of the centre has now been completed, and the equipment installation phase will now begin. Development of the inside of the facility is still ongoing, with the centre scheduled to fully open in summer 2023.

Professor Mohamed Pourkashanian, Managing Director of the Sustainable Aviation Fuels Innovation Centre and Director of the University of Sheffield Energy Institute, said: “It is fantastic to see the progress of the construction of the Sustainable Aviation Fuels Innovation Centre, which has been a smooth and efficient process thanks, in part, to our contractors, Hobson and Porter.

“The building includes some bespoke and highly technical elements, such as an APU acoustic test cell and a high-pressure high temperature combustion test cell. SAF-IC has been built with specialist elements to facilitate hydrogen, zero carbon fuels and advanced combustion research, all of which will help us to carry out vital testing.

“Our SAF characterising laboratory will provide fast, cost effective and unique capabilities for testing new fuels, with the state-of-the-art equipment that no other academic research centre has, such as a GC-GC-ToF-MS, and ICP-OES. Now we will begin the exciting process of installing cutting-edge equipment which will help to make this centre a unique and vital asset to the UK’s aviation industry.”